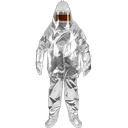

FYRAL® 9000 Fire Proximity Suit (Jacket and Pants)

JACKET -TROUSERS - HOOD - HELMET - GLOVES - BOOTS - GAITERS

Where Maximum Safety Meets Comfort!

FYRAL® 9300 Aluminized Fire Proximity Suit (Jacket and Pants) which maximizes your safety in challenging fire conditions, protects all parts of the body, including the head, hands, and feet, against the harmful effects of high heat, flames, and intense radiant heat. With its advanced design and high-quality materials, it is an excellent choice for professionals working in demanding conditions.

Key Features:

Heat and Flame Resistance: Offers effective protection against high temperatures and flames.

Ergonomic Design: Provides comfortable movement with an ergonomic structure compliant with EN ISO 13688 standards.

Six Layer Structure: Designed with a six-layer fabric for superior protection against high temperatures and flames.

Layered System:

Outer Layer: Aluminized fiberglass fabric provides protection with its resistance to high heat and heat-reflective properties.

Heat Barrier: 100% Kermel® nonwoven fabric is used in 4 layers to create air spaces

Inner Layer: Provides extra comfort and safety thanks to a special blend of high-performance fibers such as Lenzing™FR, Aramid, Polyamide, and Belltron®.

Standard Accessories:

Complete protection with integrated hood, gloves, and gaiters.

Design:

Jacket: Compatible with respiratory apparatus, front zipper for easy use. (*)

Pants: Adjustable straps and practical ankle cuffs ensure a perfect fit.

Hood: Offers panoramic view and maximum freedom of movement.

Gloves: Special layered, 5-finger design.

Gaiters + Protective Boots: Aluminized cover compatible with firefighter boots, compliant with EN 15090 and EN 20345 standards.

Certifications and Standards:

CE Certification: Holds an EU Type Examination Certificate according to (EU) 2016/425 PPE regulation and carries the CE mark.

EN 1486 Certified: Provides maximum protection by offering heat and flame resistance for flame proximity suit.

EN ISO 13688: Meets ergonomic and design requirements.

General Features:

Comfortable Fabric: With its durable and flexible structure, this fabric provides comfort and protection during extended use.

High-Quality Fastenings: Equipped with flame-resistant black textile zippers (Velcro) and FR-type zippers.

Durable Stitching: Stitched with 100% Aramid threads for enhanced durability and protection

Enhanced Protection: Front flap over the zipper prevents flame ingress, providing superior protection.

Why Choose FYRAL® 9300?

FYRAL® 9300 Aluminized Fire Proximity Suit (Coverall) is the perfect solution for professionals who require maximum protection without compromising on comfort. Made with advanced materials and cutting-edge technology, this suit offers unique defense against hazards:

Protection Against Hazards: Provides the best protection against high heat and flames.

Enhanced Comfort: The 6-layer system ensures long-lasting and high-level protection in demanding conditions.

Durability: High-quality construction and materials provide enduring performance even in the toughest environments.

Applications:

Firefighting teams directly involved in fire intervention operations

Industrial facilities

Emergency response teams

Mining and petrochemical industries

Foundries and metallurgy plants

Power generation plants

Standards:

Category III

CE Mark

MED Approval (Wheelmark)

EN 1486:2007

EN ISO 11612 Heat & Flame

Letter A (EN 15025) This test consists of applying a flame to a fabric sample for 10 seconds. To pass the test, the after flame & smoulder times and formation of holes must be within the tolerances within the standard. The application of a flame can take place in two ways: Code Letter A1 Surface Ignition, ISO15025 A Procedure A (leads to Class A1), the flame is applied horizontally to the face of the fabric No specimen shall permit any part of the lowest boundary of any flame to reach the upper or either vertical edges No specimen shall give hole formation of 5mm or greater in any direction, except for an inter-lining that is used for specific protection other than heat and flame protection. No specimen shall give flaming or molten debris The mean value of after flame time shall be ≤ 2s The mean value of afterglow time shall be ≤ 2s Code Letter A1 Edge Ignition, ISO15025 B Procedure B (leads to Class A2), the flame is applied to the bottom edge of the fabric sample. No specimen shall permit any part of the lowest boundary of any flame to reach the upper or either vertical edges No specimen shall give flaming or molten debris The mean value of after flame time shall be ≤ 2s The mean value of afterglow time shall be ≤ 2s Letter B (ISO 9151) Convective Heat: determination of the heat transmission when exposed to flames. The sample is held above the flame and the rise in temperature on the topside of the sample is measured with a calorimeter. The length of time the sample can remain exposed before its temperature rises by 24 °C is determined. B1: 4 < 10 seconds, B2: 10 < 20 seconds, B3: 21 seconds and longer Letter C (ISO 6942) Exposure to Radiant Heat. In this test, a fabric sample is exposed to radiant heat (infrared rays). The temperature on the reverse (unexposed) side of the sample is registered using a calorimeter. Subsequently, the length of time the sample the sample can remain exposed before its temperature rises by 24°C is measured. The test procedure is the same as ISO 11611, but the classification is different: C1: 7 < 20 seconds, C2: 20 < 50 seconds, C3: 50 < 95 seconds, C4: 95 seconds and longer Letter D and E (ISO 9185) D = Aluminium E = Molten Iron Determining the level of protection against spatters of molten metal. A membrane (with similar properties to human skin) is attached to the reverse of the fabric sample sequentially rising quantities of molten metal (Aluminium or Iron as applicable) are splashed on the sample. The quantity of molten metal which deforms the membrane is determined. The classification for molten aluminium is: D1: 100 < 200 grams, D2: 200 <350 grams, D3: 350 grams and more The classification for molten iron is: E1: 60 < 120 grams, E2: 120 < 200 grams, E3: 200 grams and more Letter F (ISO 12127) This is a new test to establish a value for contact heat. The classification in this respect: F1: 5 < 10 seconds, F2: 10 < 15 seconds, F3: 15 seconds and longerDetails

Споделете :

| Големини - Облека | S - Small or M - Medium or L - Large or XL - XLarge or XXL - XXLarge |

Once the user has seen at least one product this snippet will be visible.